Here is the title one h1 placeholder text

220kV and below oil-immersed power transformers

Key words:

220kV and below oil-immersed power transformers

Classification:

- Product Description

-

- Commodity name: 220kV and below oil-immersed power transformers

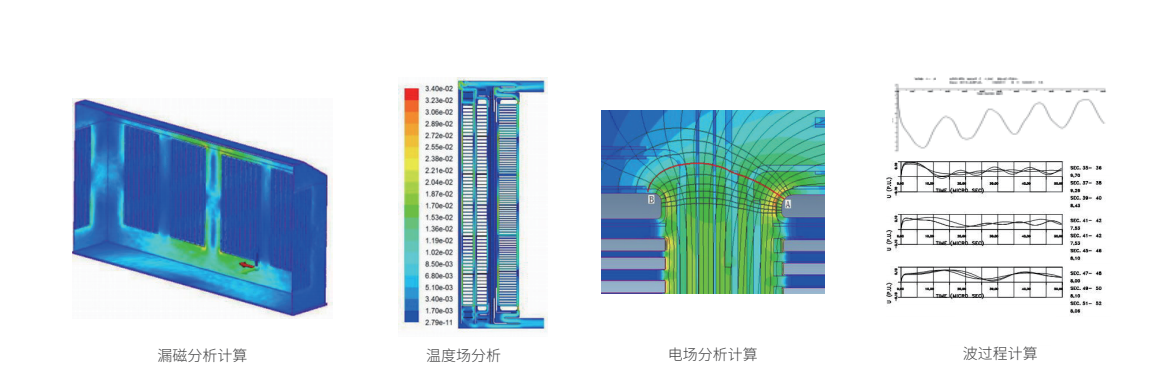

The company has a professional technical team with the design capabilities and process guidance for various transformers rated at 500kV and below. They are capable of simulating and analyzing the electromagnetic field, temperature field, and wave processes of transformers, and selecting the optimal design方案.

Purpose: Used for voltage transformation and power transmission in power systems such as power grids and industrial enterprises; used for boosting and transmitting electricity in power plants.

Voltage level: 35~330kV

Capacity range: Below 400MVA

The product features reliable insulation, low noise, low temperature rise, low partial discharge, and strong short-circuit resistance.

Technical capabilities

The company has a professional technical team capable of designing various transformers at 500kV and below, with the ability to simulate and analyze the electromagnetic field, temperature field, and wave processes of transformers, and select the optimal design scheme.

- Using wave process calculation analysis software to calculate potential distribution, repeatedly adjusting to ensure a reasonable gradient distribution of the coils, while performing field strength verification on the body to determine the main longitudinal insulation structure parameters, ensuring reliable electrical strength.

- Using electric field analysis software to analyze the detailed distribution of local field strength, targeted measures such as structural adjustments, rounding electrodes, segmenting oil gaps, or adding insulation, and shaping shields at areas of concentrated local field strength are taken to greatly reduce partial discharge.

- Using specialized leakage magnetic analysis and short-circuit mechanical force calculation software to analyze the stress conditions of the transformer under the worst-case scenario without considering system impedance, which serves as the design basis for transformer strength design, ensuring sufficient short-circuit resistance.

- Using temperature field and flow velocity field analysis software to calculate the oil flow velocity at various points in the coil, calculating the temperature rise at hot spots in the coil, and taking targeted optimization measures to reduce coil temperature rise, extending the transformer’s lifespan.

- The company has a good cooperative relationship with research institutes and universities, complementing each other's strengths to develop various new products, possessing sufficient and lasting innovation motivation.

Structural characteristics

- The oil tank structure is either bell-shaped or barrel-shaped, with the tank walls reinforced with plate or folded edge structures to improve mechanical strength. The connection between the upper and lower sections of the oil tank can be bolted or welded.

- The transformer oil storage cabinet can withstand full vacuum strength. After all transformer accessories are assembled, oil can be injected after creating a full vacuum at the top of the storage cabinet, effectively preventing the formation of bubbles in the insulation components and inside the transformer, reducing partial discharge.

- A special positioning structure is used at the upper and lower parts of the transformer body, which is reliable and resistant to transport impacts, meeting the requirement for on-site installation without a lifting cover.

- The sealing surfaces of the transformer, including the bushings, adopt a hard connection structure with limit grooves, using high-quality sealing components, and applying sealing glue during installation to ensure no leakage.

- The inner side of the large transformer oil tank is equipped with magnetic shielding or copper shielding based on the results of leakage magnetic analysis software, effectively suppressing temperature rise of the tank wall and reducing losses.

The entire production process of our transformers is quality controlled according to an advanced process management system. Processes such as wire, insulation material production, coil manufacturing, and body assembly are all conducted under air cleanliness control according to dust-free work area requirements, with dust levels controlled below 3μg/cm2•day.

Related Products

Product inquiry

Note: Please leave your E-mail and our professionals will contact you as soon as possible!

Contact Information

Sales Hotline:0519-85779127

Address: No.88, 4th Road, Environmental Protection Industrial Park, Xinbei District, Changzhou City, Jiangsu Province

Fax: 0519-85779092 / 0519-85773808

Postcode: 213033

E-mail:tpydl@163.com

Official Public Number

Official Mobile Station

Copyright©Changzhou Pacific Power Equipment (Group) Co., Ltd.